If you’re in the manufacturing industry, you’ve probably heard about laser cutting, and for good reason. Boasting precision, speed, and versatility, it has quickly become a catalyst for growth and success in the manufacturing world. In the following paragraphs, we'll uncover exactly what makes laser cutting so special and its positive influence on the manufacturing sector.

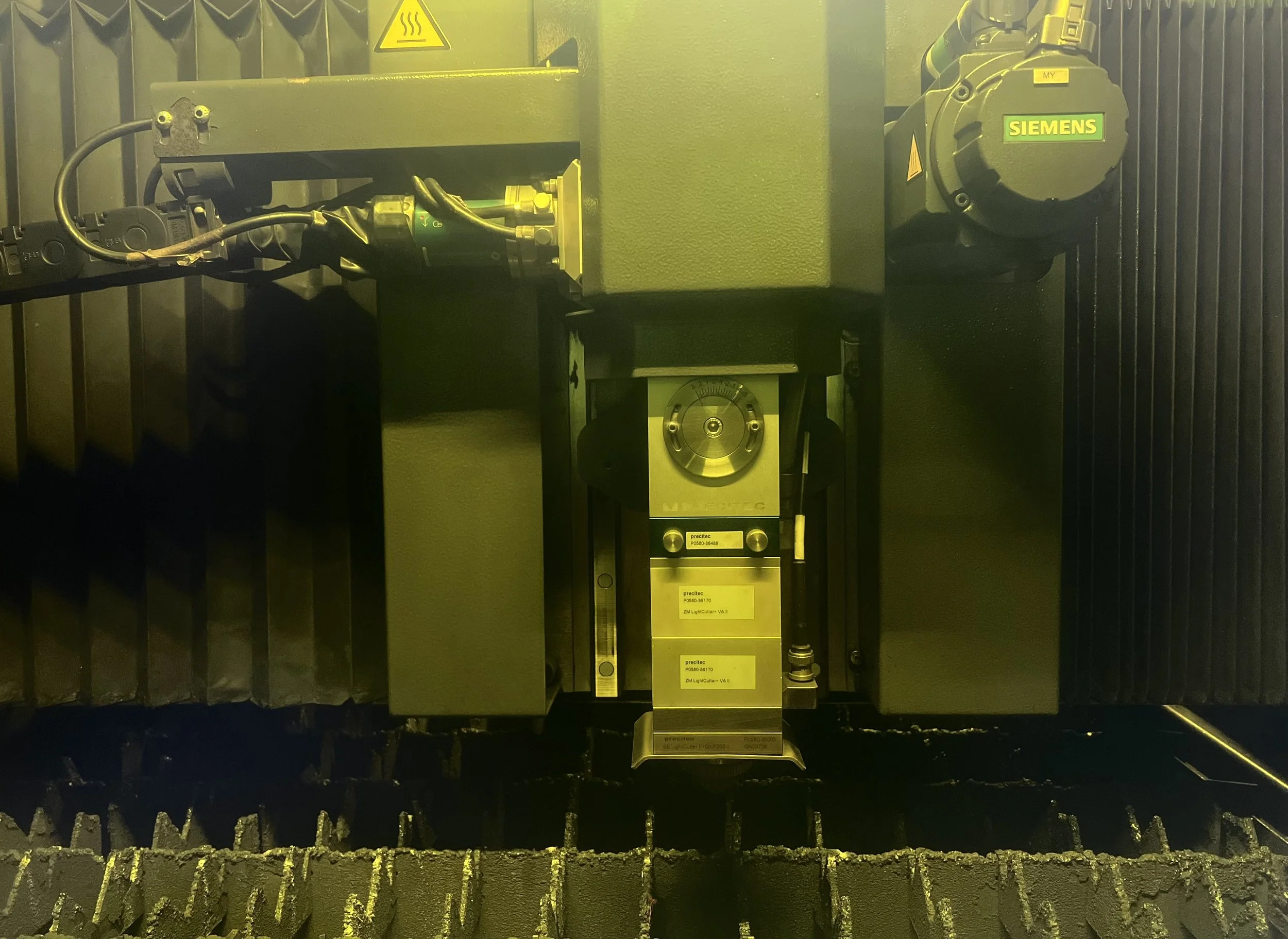

Before we explore the topic in further detail, let's briefly take a look at the basics of laser cutting and the mechanics behind its functionality. In essence, laser cutting is a computer-controlled process that uses a high-powered laser beam to cut through materials. The laser beam, typically generated by a CO2 or fiber laser, follows a programmed path based on a CAD (Computer-Aided Design) file, resulting in a clean and accurate cut.

Laser cutting is all about precision and flexibility. With most systems capable of maintaining tolerances as tight as ±0.1 mm (0.004 inches), the final cut dimensions remain incredibly close to their intended measurements. The precision of laser cutting is largely determined by three key factors: the specific laser source employed, the superiority of the optics, and the exactness of the motion control mechanism, but we’ll uncover that further in another article. What’s most exciting is the way laser cutting is driving innovation across industries with its ability to execute complex geometries and intricate design details. The integration of laser cutting at Ideal Design has not only enabled us to handle greater production volumes, but also expand our project capabilities and improve turnaround. Imagine being able to produce highly customized products tailored to individual customer needs at scale – that's the power of laser cutting in action.

But it's not just about creating unique products; laser cutting is also revolutionizing the speed at which we develop them. Gone are the days of extensive prototyping and product development cycles. With laser cutting, designers and engineers can re-iterate designs quickly, test prototypes, and bring products to market faster than ever before. And let's not forget about the impact this has on supply chain efficiency. Laser cutting’s speed advantage enables manufacturers to accelerate production resulting in shorter lead times, increased productivity, and the ability to take on more projects.

Laser cutting is also perfectly positioned to drive the adoption of Industry 4.0 principles. By integrating with other advanced technologies like artificial intelligence and the Internet of Things, laser cutting is paving the way for smarter, more efficient, and more flexible manufacturing processes.

So what does all this mean for the future of manufacturing? As laser cutting continues to evolve and become more accessible, its potential to transform the industry will only continue to grow. Manufacturers who embrace this technology will be better equipped to stay competitive, innovate, and respond to the ever-changing demands of the market.